Quality Control

ONI Shopfitting always does its best to deliver projects with a wholehearted attitude, focusing not only on the quality control of the display equipment, but also on the high-security packaging method. Before loading, we will photograph and inspect each piece of goods.

Production Line

The production process of storefront fixtures encompasses multiple stages from design to finished products, with each step requiring strict control to ensure the final products meet usage requirements and quality standards.

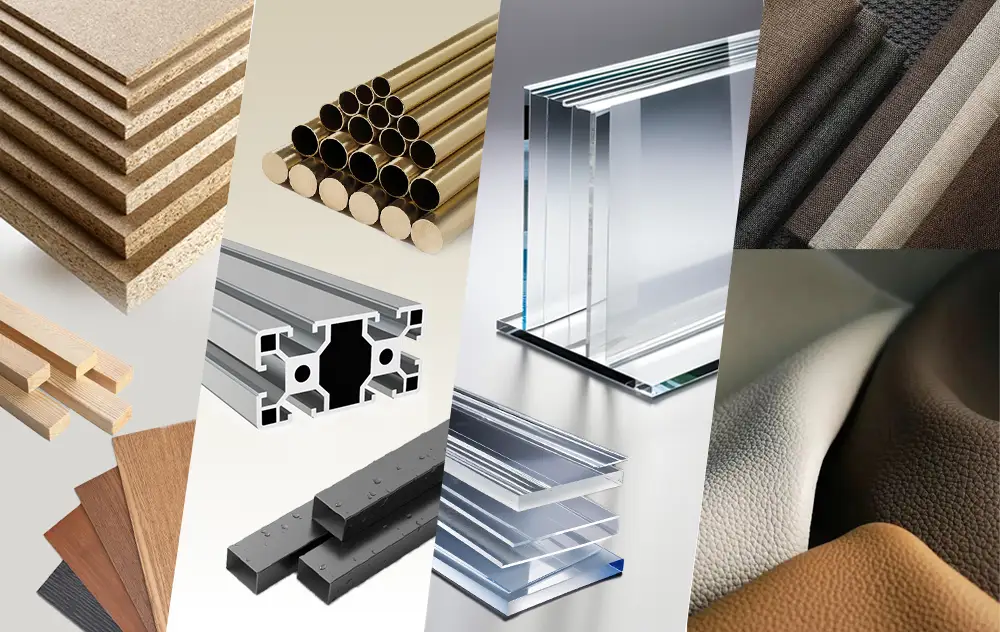

Material Selection and Procurement

Materials are selected based on design functions. Common materials for storefront fixtures include wood (solid wood, chipboard board, MDF), metals (steel, aluminum), glass, acrylic glass display case components, and decorative finishes like leather or fabric.

Cutting and Forming Processing

Corresponding cutting and forming processes are carried out for different materials:

- Wood Processing

- Metal Processing

- Acrylic/Glass Processing

Surface Treatment

Surface treatment not only improves the appearance of store fixtures but also enhances their durability:

- Wood Surface Treatment

- Metal Surface Treatment

- Acrylic/Glass Surface Treatment

Installation of Functional Accessories

According to the functional requirements of the store fixtures, corresponding accessories are installed, such as hooks, laminates, lighting (LED light strips, spotlights, etc.), slide rails, locks, label slots, etc.

During installation, it is necessary to ensure that the accessories are positioned accurately and function smoothly. For example, the installation of lighting should ensure uniform lighting effect, and the load-bearing capacity of hooks should meet the design standards.

Assembly and Joining

Quality Inspection

Thorough testing ensures that the final storefront fixtures meet performance standards:

- Check whether the appearance has scratches, deformation, color difference, coating peeling, etc.;

- Test the structural stability, such as shake test and load-bearing test (to ensure it can bear the specified weight without deformation);

- Verify the use effect of functional accessories, such as whether the drawer slides smoothly and whether the lighting works normally.

- If unqualified products are found, they need to be repaired or scrapped in a timely manner until they meet the quality standards.

Packaging and Delivery

Strong and Safe Packaging for Delivery

We take care of all the logistics to ensure that your custom displays and mounting components arrive hassle-free. Each product is fully inspected and accepted before shipment

1. Stretch Wrap

2. Bubble Wrap

3. Corner Protector

4 .Top Plate Box

5.Waiting for Shipment

6. Cargo Loading

Contact Us